From the Field: Mastering Superheat in Commercial Refrigeration: The Key to Efficient Cooling Systems

In the world of commercial refrigeration, accurate control of the refrigeration cycle is vital to keeping your walk-in coolers, reach-in display cases, and freezer units running at peak performance. One of the most crucial indicators of proper operation is Superheat—a parameter that, when properly understood and managed, can be the difference between reliable equipment and costly service calls.

This article explores what superheat is, why it matters, how to measure it manually, and how it affects the health of your refrigeration system. Whether you're a grocery store manager, convenience market owner, or operate refrigerated storage for liquor stores, produce stands, or wholesale warehouses, this guide is packed with actionable insights.

What Is Superheat?

Superheat is the temperature of a vapor refrigerant above its boiling (saturation) temperature at a given pressure. It tells us that all the liquid refrigerant has evaporated into gas before entering the compressor.

Formula:

Superheat = Measured Suction Line Temperature - Saturation Temperature (from pressure)This measurement confirms two key facts:

All liquid refrigerant has boiled off before reaching the compressor.

The compressor is protected from liquid slugging.

Why Is Superheat Important?

In systems with Thermostatic Expansion Valves (TXVs) or Capillary Tubes, controlling superheat ensures that:

The evaporator coil is fully utilized.

The compressor receives vapor, not liquid (which can cause damage).

Energy efficiency is maximized.

Optimal superheat levels (typically 6°F–12°F for most walk-in coolers) improve system efficiency, compressor longevity, and temperature stability in commercial refrigeration systems used in gas stations, grocery chains, and restaurants.

Tools Needed to Measure Superheat

To manually calculate superheat, the following tools are required:

Digital Manifold Gauge Set or Analog Gauges – To measure suction pressure.

Temperature Clamp Probe – To measure suction line temperature.

PT (Pressure/Temperature) Chart or App – To convert suction pressure to saturation temperature.

Refrigerant ID Tag – Ensure the correct refrigerant type (e.g., R-404A, R-448A).

Step-by-Step: How to Measure Superheat Manually

Step 1: Connect your gauges to the suction service port of the evaporator outlet or compressor inlet.

Step 2: Attach a temperature probe to the suction line near the port—ensure it's insulated from ambient air.

Step 3: Record the suction pressure and use a PT chart to determine the saturation temperature.

Step 4: Measure the actual line temperature using the clamp.

Step 5: Subtract the saturation temperature from the measured suction line temperature.

Example Calculation:

Measured suction line temp = 48°F

Saturation temp (based on 62 psi R-404A) = 34°F

Superheat = 48 - 34 = 14°F

Scientific Principle Behind Superheat

Superheat hinges on thermodynamic phase change. As a liquid refrigerant absorbs heat in the evaporator, it reaches its saturation point, where it turns to vapor. Adding more heat raises its temperature without increasing pressure—this added heat is the superheat.

This concept is governed by Gay-Lussac's Law (Temperature ∝ Pressure at constant volume) and latent heat of vaporization in phase transition.

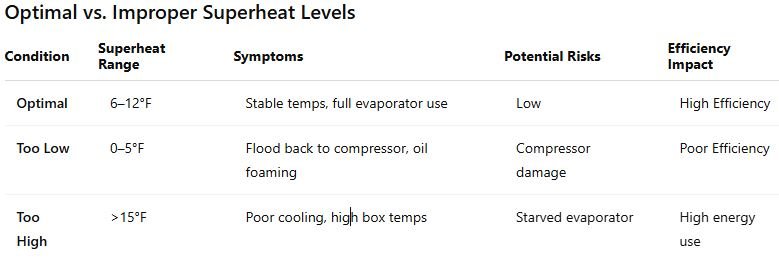

Optimal vs. Improper Superheat Levels

Troubleshooting Abnormal Superheat

High Superheat Symptoms:

Warm product temperatures

Compressor running hot

Ice forming only at evaporator inlet

Possible Causes:

Low refrigerant charge

TXV restriction or malfunction

Plugged filter-drier

Remedies:

Leak check and recharge refrigerant to specs

Test and replace faulty TXV

Replace restricted filter-drier

Low Superheat Symptoms:

Compressor short cycling

Oil in suction line

Ice on suction line or compressor

Possible Causes:

Overcharged system

TXV overfeeding

Sensing bulb not secured properly

Remedies:

Remove excess refrigerant

Adjust or replace TXV

Secure/relocate sensing bulb to correct spot on suction line

Efficiency Benefits of Proper Superheat

Keeping superheat within range helps ensure:

Full utilization of the evaporator coil

Reduced compressor cycling and energy use

Stable box temperatures (essential for grocery freezers, beer caves, and walk-in coolers)

Final Thoughts for Business Owners

Whether you're operating a cold vault in a liquor store, maintaining refrigerated produce shelves in a supermarket, or running walk-in freezers in a wholesale warehouse, superheat should be part of your regular maintenance check.

At Jadeco Commercial Refrigeration, our certified technicians are trained to check, calibrate, and optimize superheat settings on all commercial refrigeration systems. Proper superheat control ensures your equipment runs efficiently, safely, and cost-effectively.

Contact us today for maintenance programs, emergency service, or new refrigeration system installations tailored for gas stations, convenience markets, grocery stores, and retailers who can’t afford warm coolers.

Keywords: Superheat Refrigeration, Walk-In Cooler Repair, Commercial Refrigeration Maintenance, TXV Adjustment, Low Superheat Symptoms, High Superheat Fix, Refrigeration Contractors for Grocery Stores, Display Case Refrigeration, Convenience Store Cooler Service, Warehouse Freezer Maintenance