Inside the Chill: How a Walk-In Cooler Keeps Its Cool – A Deep Dive Into the Refrigeration Cycle

Whether you're running a restaurant, managing a grocery store, or operating a cold storage warehouse, the humble walk-in cooler is the silent hero of food safety and product longevity. Behind those chilled shelves lies a precision-engineered refrigeration cycle governed by science, ensuring your inventory stays fresh 24/7. At Jadeco Commercial Refrigeration, we break down this process to show exactly how heat is removed from walk-in coolers, freezers, and refrigerated display cases and transferred to the outside world.

The Four Main Components of the Refrigeration Cycle

At the heart of every walk-in cooler lies a closed-loop refrigeration system made up of four primary components:

1. Evaporator Coil (Located Inside the Cooler)

2. Compressor (Usually Mounted Externally or Remotely)

3. Condenser Coil (Heat Rejection Component)

4. Expansion Valve (Thermal Metering Device)

Each component plays a role in controlling the pressure and temperature of refrigerant, thereby enabling the transfer of unwanted heat from inside the cooler to the outside air.

Step-by-Step: The Refrigeration Cycle

1. Evaporator Coil – Where the Heat is Stolen

· Physical State of Refrigerant: Low-pressure, low-temperature liquid/vapor mix (evaporates to a vapor)

· Scientific Principle: Latent heat of vaporization (Evaporative Cooling)

· Keywords: evaporator coil problems, poor cooling, iced evaporator, superheat measurement, TXV issues

The cycle begins inside the walk-in cooler or refrigerated case, where cold refrigerant in the evaporator coil absorbs heat from the surrounding air. This energy absorption causes the refrigerant to change physical state from a liquid to a gas. The phase change is governed by the principle of latent heat. The temperature difference between the refrigerant entering as a liquid and leaving as a gas is known as superheat, typically 6–10°F.

The Low-pressure, cold liquid refrigerant enters the evaporator coil and passes through a coper tube jacketed in aluminum fins (Heat Sink) which increase the surface area that the air in the cooler contacts allowing for efficient transfer of heat from the air to the liquid refrigerant. As the refrigerant absorbs heat. The energy absorbed from that heat changes the physical phase of the refrigerant from a liquid to a vapor (boiling) without increasing its temperature effectively 'stealing' the heat efficiently. After the liquid is fully vaporized, it will continue to absorb heat from the cooler, however the vapor refrigerant now begins to increase in temperature loosing it’s heat absorption ability and efficiency. Ideally the temperature gain through this process will be between 6°F and 12°F above the vapor point of the refrigerant in use. The temperature variance between vapor point of the cool liquid entering the evaporator coil and the warmer vapor leaving the coil is known as ‘superheat’.

Superheat is a measurement used in the refrigeration industry to describe the temperature difference across the evaporator coil. More specifically the temperature difference between the vapor leaving the evaporator coil and the vapor point of the refrigerant being used at the current pressure. A vapor P-T (Pressure -Temperature) chart is used to determine the correct vapor point for each refrigerant type. Typically the calculated superheat should fall into the range of 6-12 degrees Fahrenheit above the vapor point. If the superheat is too low (<6°F) there is a risk that liquid refrigerant will enter the compressor (liquid slugging), which can cause severe damage as liquids are not compressible. If the superheat is too high (>12°F): Indicates inefficient evaporator usage; too much of the coil is being used to superheat already vaporized refrigerant instead of absorbing heat for vaporization.

Problem Point:

· Symptom: Ice buildup on the coil or poor cooling

o Cause: Low airflow (dirty evaporator fan or coil), low refrigerant charge, or TXV malfunction

· Keywords: commercial compressor troubleshooting, refrigeration compressor repair, liquid slugging damage

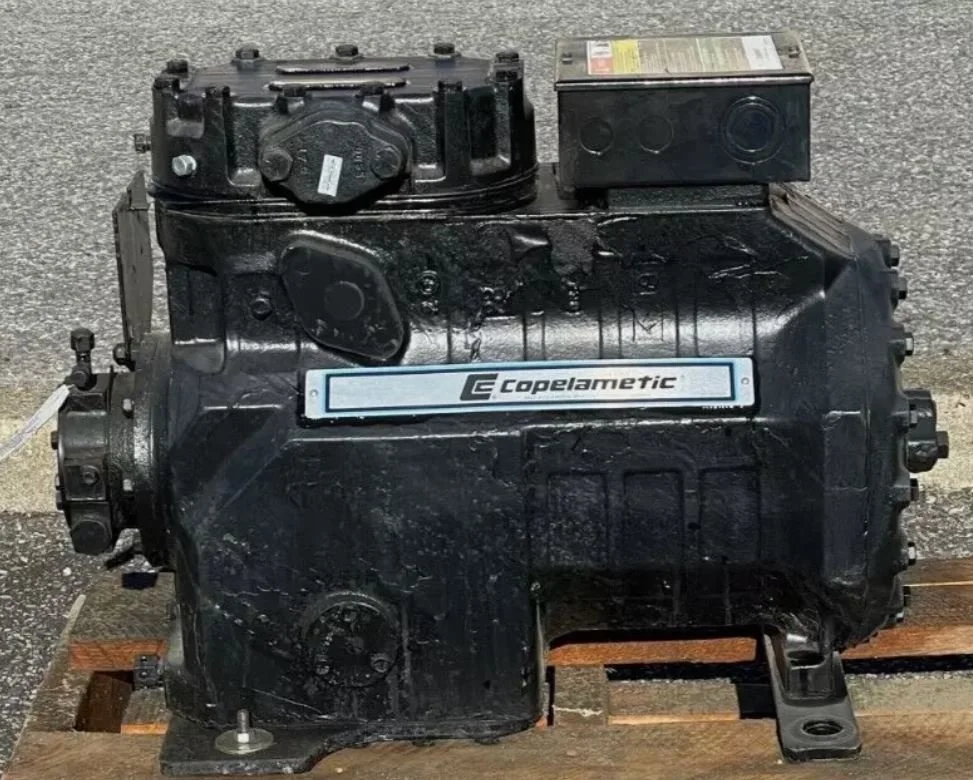

2. Compressor – The Heart of the System the Pressure Builder

· Physical State of Refrigerant: Low-pressure vapor in, high-pressure vapor out

· Scientific Principle: Thermodynamic compression (adiabatic or near-adiabatic), Boyle’s and Charles’s and Gay-Lussac’s Laws. The process conserves mass and energy while altering state parameters.

After absorbing heat, the refrigerant vapor travels to the compressor, where it is mechanically compressed. During compression the pressure and temperature of the vapor dramatically increase, without changing its state. High-pressure vapor is then sent to the condenser.

Compressor Internal Function:

The compressor is essentially a mechanical pump designed to increase the pressure and temperature of the refrigerant vapor. It relies on several precision components working in harmony:

· Pistons and Connecting Rods: In reciprocating compressors, pistons are driven by a crankshaft and rods to compress the vapor. The movement reduces the volume inside the cylinder, increasing pressure (Boyle’s Law).

· Reed Valves or Plate Valves: These one-way valves control refrigerant flow. Suction valves open during piston downstroke, allowing low-pressure vapor in. Discharge valves open during upstroke, forcing high-pressure vapor out.

· Crankshaft and Bearings: Convert rotary motion to linear motion for piston actuation. Bearings reduce friction and wear.

· Electric Motor Windings: Provide the driving force for the crankshaft. Can be externally or hermetically sealed within the compressor shell.

Problem Point:

· Symptom: Short cycling, tripped breakers, or buzzing

o Cause: Overheating, liquid slugging (from improper vaporization), or electrical faults

· Symptom: Poor compression, short cycling, or backflow of gas

o Cause: Broken Reeds/Valves:

· Symptom: Noise, overheating, eventual seizure

o Cause: Worn Bearings/Rods:

· Symptom: Burned windings, open circuits, failed start/run

o Cause: Electrical Faults

Why vapor state is critical:

Compressors are designed to compress gas only. If liquid refrigerant enters the compressor (“liquid slugging”), it can damage the valves or rods because liquids are incompressible. Proper vaporization in the evaporator is crucial for compressor health.

3. Condenser Coil – Dumping the Heat – Where Heat is Expelled

· Physical State of Refrigerant: High-pressure vapor condenses into high-pressure liquid

· Scientific Principle: Latent heat of condensation and convection

· Keywords: dirty condenser fins, failed condenser fan, refrigeration heat rejection

In the condenser coil, the high-pressure vapor releases its absorbed heat to the outside air often with the help of a condenser fan. The refrigerant once again passes through a coper coil jacketed in aluminum fins (Heat Sink). As the refrigerant loses heat, it condenses into a high-pressure liquid. This phase change again occurs at a constant temperature but releases a substantial amount of energy into the environment. The refrigerant is then passed to an expansion valve where it is depressurized and cooled further.

Problem Point:

- Symptom: High head pressure or hot air venting from condenser

- Cause: Dirty condenser coil, failed fan motor, or insufficient ventilation

4. Expansion Valve – The Pressure Drop – Expansive Cooling

· Physical State of Refrigerant: High-pressure liquid rapidly becomes low-pressure liquid/vapor mix reducing in temperature.

· Scientific Principle: Thermodynamic throttling (isenthalpic expansion, expansive cooling) Gay-Lussac’s Law

· Keywords: TXV adjustment, expansion valve troubleshooting, inconsistent walk-in cooler temps

Now a high-pressure liquid, the refrigerant enters the thermal expansion valve (TXV or EEV), where it is ‘throttled’ (suddenly reduced in pressure). This rapid pressure drop causes the refrigerant to cool dramatically. Some of it flashes into a vapor, but most remains a cold liquid, ready to absorb heat again in the evaporator.

Problem Point:

· Symptom: Inconsistent cooling or rapid temperature swings

· Cause: Stuck, clogged, or misadjusted expansion valve

Closing the Loop

From here, the chilled refrigerant re-enters the evaporator coil, and the cycle repeats. Each component relies on the others, and small failures in one part can cascade through the entire system.

Common Symptoms and Diagnoses by Cycle Stage

Component: Evaporator Coil

Symptoms: Poor cooling, iced lines, compressor floodback

Typical Problem: Icing, low airflow, undercharge

Component: Compressor

Symptoms: Loud noises, breaker trips, loss of suction

Typical Problem: Slugging, overheating, electrical fault

Component: Condenser Coil

Symptoms: High head pressure, short cycling

Typical Problem: Dirty fins, failed fan, airflow issues

Component: Expansion Valve

Symptoms: Warm box, temp swings, evaporator icing

Typical Problem: Improper superheat, clog, oversupply

Why Understanding This Cycle Matters

Whether you're a refrigeration service technician, restaurant owner, or facility manager, understanding this process helps you recognize issues before they become emergencies. It also aids in preventative maintenance, compliance with cold chain standards, and optimizing energy efficiency. Technicians who understand the thermodynamics behind this process can troubleshoot faster and prevent expensive component failures. Business owners gain confidence knowing how and why their system keeps running—and what signs point to problems before they lead to spoiled product or downtime.

When heat moves out of your cooler, it’s not magic—it’s science, precision, and engineered reliability. Every cycle, every second.

At Jadeco Commercial Refrigeration, We Keep You Cool

From walk-in cooler repair to display case maintenance and preventative refrigeration service plans, our expert technicians are trained in the science behind the cycle. We service all major commercial refrigeration equipment including those by HillPheonix Heatcraft, Bohn, Hussmann, True, and Beverage-Air.

We understand the value of keeping your products safe and fresh. We strive to ensure every one of our technicians has an in-depth knowledge of the refrigeration cycle and it’s relationship to keeping your coolers, display cases, and merchandisers within operational standards.